| |

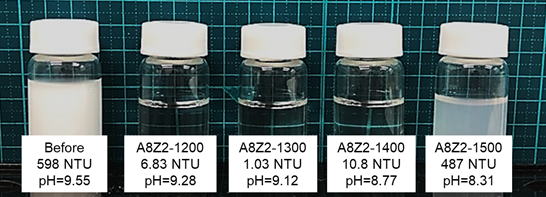

Effect of sintering temperature on water-purification

performance of Al2O3/3Y-ZrO2 membrane filters

Ceramic filters can be adapted to various liquids even under adverse conditions.

Al2O3-based composites dispersed with 3 mol%-Y2O3-doped ZrO2 (3Y-ZrO2),

or Al2O3/3Y-ZrO2, are well-known as extremely strong oxide-based ceramics.

In this study, we have focused on the Al2O3/20 wt.% 3Y-ZrO2 composites

as ceramic water filters. Disk-shape Al2O3/3Y-ZrO2 filters with different

pore structures were prepared by pressureless sintering at 1200-1500 deg

C in air. The pore-size distribution of the filters was analyzed by mercury

porosimetry. Some filtration properties, such as turbidity, were evaluated,

and the Herman and Bredee's filtration models were discussed. Among the

filters sintered at different temperatures, the Al2O3/3Y-ZrO2 filter sintered

at 1300 deg C showed the best performance due to the lack of large pores

of > ~2 micrometer. The average pore diameter of the A8Z2-1300 sample

was 64 nm, the pore volume was 0.157 cm3/g, and the open porosity was 40.2%.

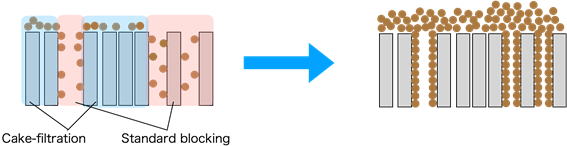

SEM observations confirmed the change of the cake-layer thickness after

the filtrations, i.e., ~27, ~17, ~15, ~2 micrometer for the A8Z2-1200,

1300, 1400 and 1500 samples, respectively, which revealed that the actual

filtration in this study was the combination of (i) the standard blocking

with the larger pores at the initial stage and (ii) the cake-filtration

with the smaller pores at the middle and late stages.

|

|

R. Hatori and Y. Suzuki, J. Mater. Sci., 56 [16] 9668-9677 (2021).

https://doi.org/10.1007/s10853-021-05927-w

|

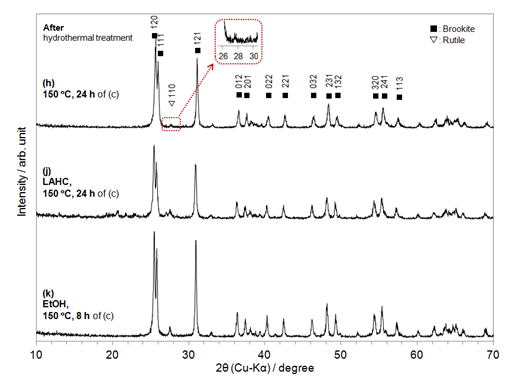

Facile synthesis of >99% phase-pure brookite TiO2 by hydrothermal conversion from Mg2TiO4

The synthesis of pure brookite is generally much more difficult than

that of pure anatase. The hydrothermal conversion, recently developed by

Kozawa et al., is a facile method to synthesize brookite TiO2 from inverse spinel-type Mg2TiO4 under a mild hydrothermal condition e.g. in 1 M HCl solution at 100 degC.

However, slight rutile TiO2 is usually co-existed under the reported conditions. The aim of this study is to prepare a high-purity brookite TiO2 powder by the hydrothermal conversion from Mg2TiO4. We investigated the conditions of Mg2TiO4

preparation and hydrothermal conversion, and it was found that the most

important factor for the high-purity brookite synthesis, i.e.

decreasing the co-existing rutile TiO2, was to prepare the Mg2TiO4 precursor without MgTiO3. Using an MgO-rich composition and adding a second calcination step for

the Mg2TiO4 preparation yielded a high-purity (99.3 wt%) brookite powder with a surface

area of 27.7 m2/g. Under the current experimental conditions, addition of a surfactant

or an alcohol for the hydrothermal treatment was not apparently effective

for the high-purity brookite synthesis.

Mg2TiO4からの水熱転換法による>99%相純粋なブルッカイト型TiO2の易合成

純粋なブルッカイトの合成は、純粋なアナターゼの合成よりもはるかに困難である。最近、Kozawaらによって開発された水熱転換法は、例えば100℃の1M HCl溶液中という穏やかな熱水条件下で、逆スピネル型Mg2TiO4からブルッカイトTiO2を合成する簡便な方法である。しかしながら、報告された条件下では通常、わずかなルチルTiO2が共存する。

本研究の目的は、Mg2TiO4からの水熱転換法によって高純度のブルッカイトTiO2粉末を調製することである。Mg2TiO4の調製と水熱転換の条件を検討したところ、高純度のブルッカイトの合成、すなわち共存するルチルTiO2の低減にとって最も重要な要素は、MgTiO3を含まないMg2TiO4前駆体を調製することであった。MgOが豊富な組成物を使用し、Mg2TiO4調製物のための第2の仮焼工程を加えることにより、27.7m2/gの比表面積を有する高純度(99.3wt%)ブルッカイト粉末が得られた。現在の実験条件下では、水熱処理時の界面活性剤またはアルコールの添加は、高純度ブルッカイト合成には有効ではなかった。

|

|

M. Machida, M. Kobayashi, Y. Suzuki, H. Abe, Ceram. Int., 44 [14] 17562-17565

(2018).

https://doi.org/10.1016/j.ceramint.2018.06.170 |

|

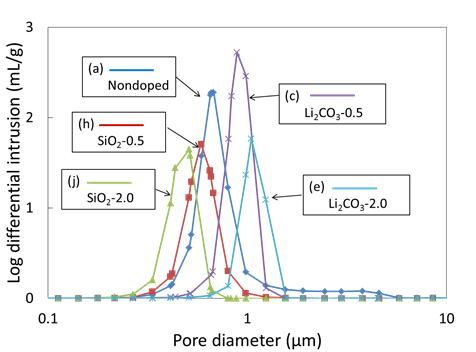

Impurity effects on phase and microstructure stabilities of reactively-sintered porous MgTi2O5

Since the thermal-expansion anisotropy of pseudobrookite-type MgTi2O5 is not as prominent as isomorphic Al2TiO5, MgTi2O5 is thermally more stable than Al2TiO5. To realize the future structural applications of porous MgTi2O5, influence of impurities on the phase and microstructure stabilities should

be studied. Here, impurity effects on phase and microstructure stabilities

of reactively-sintered porous MgTi2O5 have been studied. As model impurities, Li2CO3 and amorphous SiO2 have been selected. Li2CO3 or SiO2 powder (0.1-4.0 wt%) was added to MgCO3 (basic) and TiO2 anatase powders with a molar ratio of 1:2. Uniaxially-pressed mixed powders

were sintered at 1100 degC in air for 2 h to obtain porous MgTi2O5 bars. Appropriate Li2CO3 and SiO2 doping (~0.5 wt%) promoted uniform grain growth. However, with the excess

amount of the impurities (>2 wt%), the coefficient of thermal expansion

of Li2CO3- and SiO2-doped MgTi2O5 ceramics decreased obviously above 900 degC and 950 degC due to the secondary

sintering. To keep the fine-grained porous microstructure of Li2CO3- and SiO2-doped samples with preventing the secondary sintering, impurity levels

should be preferably limited less than ~1.0 wt%.

反応焼結多孔質MgTi2O5の相安定性および微構造安定性に及ぼす不純物の影響

擬ブルッカイト型MgTi2O5の熱膨張異方性は、同形であるAl2TiO5ほど顕著ではないため、MgTi2O5はAl2TiO5より熱的に安定である。今後、多孔質MgTi2O5を構造材料として応用するためには、相安定性および微構造安定性への不純物の影響を研究する必要がある。

本研究では、反応焼結多孔質MgTi2O5の相安定性および微構造安定性に及ぼす不純物の影響を検討した。モデル不純物として、Li2CO3および非晶質SiO2を選択した。 モル比1: 2の塩基性MgCO3およびTiO2アナターゼ粉末に、Li2CO3またはSiO2粉末(0.1-4.0 wt%)を添加した。一軸加圧した混合粉末を1100℃で空気中で2時間焼結して多孔質MgTi2O5試料を得た。適量のLi2CO3およびSiO3のドーピング(約0.5 wt%)は、均一な粒成長を促進した。しかしながら、過剰量の不純物添加(>2 wt%)では、Li2CO3およびSiO2がドープされたMgTi2O5セラミックスの熱膨張係数は、二次的な焼結により900℃および950℃以上で明らかに低下した。二次的な焼結を防止しながら、Li2CO3およびSiO2でドープされた試料の微細な多孔質構造を維持するためには、不純物レベルは、好ましくは〜1.0 wt%未満に制限されるべきであることが分かった。

|

|

X. Miao and Y. Suzuki, Ceram. Int., 44 [8] 10000-10005 (2018).

https://doi.org/10.1016/j.ceramint.2018.02.174 |

|

|

Copyright (c) 2011-2018 Yoshikazu Suzuki Laboratory, University of Tsukuba

|

|